Currently Empty: 0.00zł

Cost Accounting: Definition and Types With Examples

By analyzing variances and implementing corrective actions, standard costing fosters a culture of continuous improvement and cost optimization. Variance analysis highlights inefficiencies in the production process, enabling businesses to identify and address areas for improvement. Through variance analysis, businesses can assess https://www.instagram.com/bookstime_inc individual and departmental performance, promoting accountability and productivity.

Standard Cost Variances

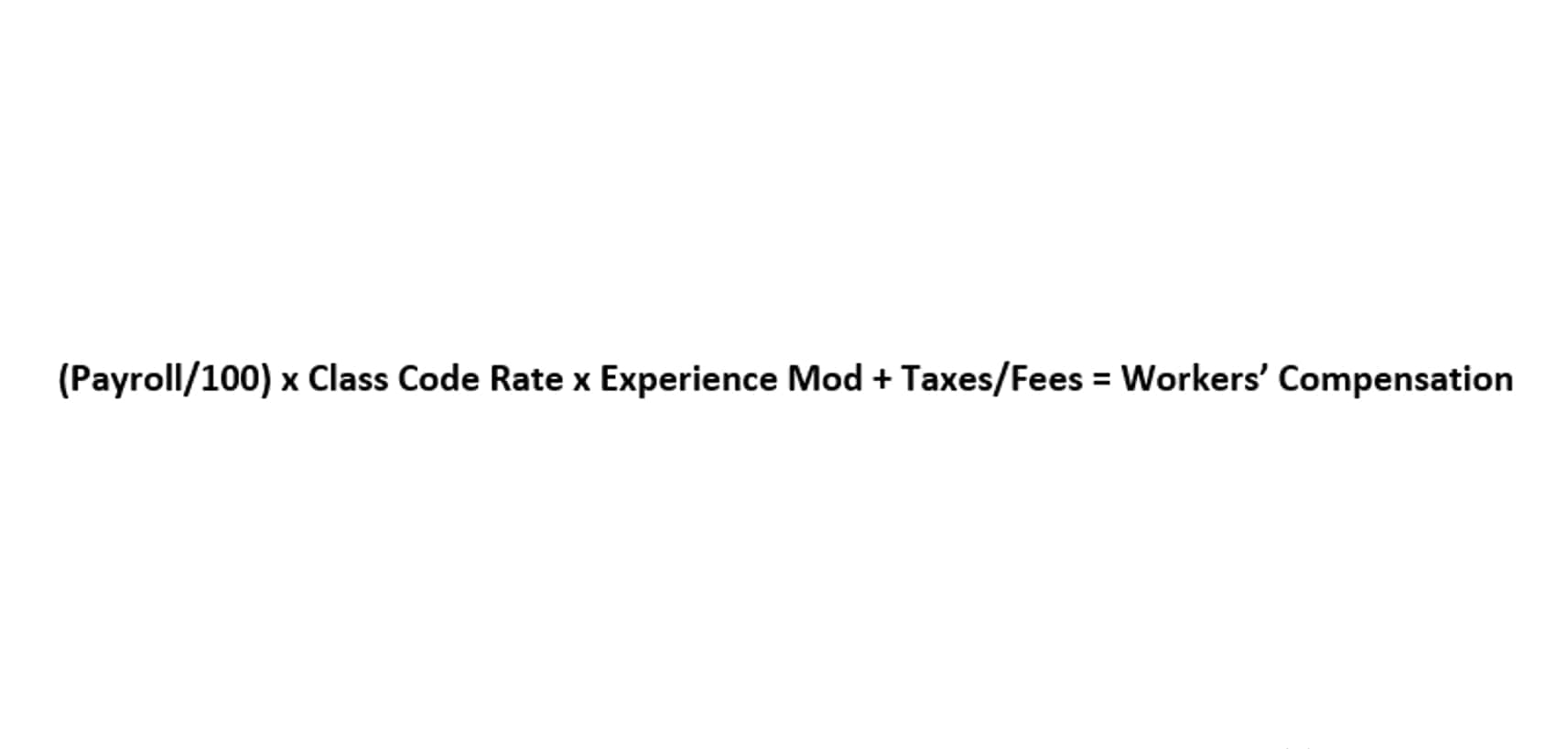

By establishing standard costs, organizations can streamline budgeting processes and enhance decision-making efficiency. The $240 variance is favorable since the company paid $0.08 per yard less than the standard cost per yard x the 3,000 yards of denim. Establishing a standard costing system for materials, labor, and overheads is a complex task, requiring the collaboration of a number of executives. A standard is a predetermined measure relating to materials, labor, or overheads. It is a reflection of what is expected, under specific conditions, https://www.bookstime.com/articles/accounting-consulting of plant and personnel.

- It needs no special calculations to determine actual unit costs during the period.

- This helps the management of the business analyze any variances between the expected costs of the business and the actual costs incurred by the business during its processes.

- By aligning their cost expectations with these benchmarks, businesses can ensure that their standard costs are competitive and reflective of broader market conditions.

- This approach helps in financial planning, decision-making, and maintaining accurate financial records, contributing to better cost control and overall operational efficiency.

To Set Standards for each Type of Cost

In a standard cost system, a company shows the cost flows between inventory accounts and into cost of goods sold at consistent standard amounts during the period. It needs no special calculations to determine actual unit costs during the period. Instead, companies may print standard cost sheets in advance showing standard quantities and standard unit costs for the materials, labor, and overhead needed to produce a certain product. Cost savings inrecord-keeping Although a standard cost system may seem torequire more detailed record-keeping during the accounting periodthan an actual cost system, the reverse is true.

Limitations of Standard costing system

Manufacturing companies use cost accounting for estimating various expenses including direct material, direct labor, or overhead. In addition to enhancing forecasting accuracy, standard costing also aids in performance evaluation. By comparing actual costs to standard costs, managers can assess the efficiency of various departments and identify areas for improvement. This comparative analysis provides a basis for setting performance targets and incentivizing cost-effective practices. Furthermore, standard costing facilitates communication across different levels of the organization, ensuring that all stakeholders have a clear understanding of financial expectations and objectives.

Nonetheless, as long as you are aware of these issues, it is usually possible standard costing system to profitably adapt standard costing into some aspects of a company’s operations. In setting standards, the key question is to decide on the type of standard to be used in fixing the cost. The main types of standards are ideal, basic, and currently attainable standards.

- Marginal costing can help management identify the impact of varying levels of costs and volume on operating profit.

- The setting up of standard costs requires the consideration of quantities, price or rates, and qualities or grades for each element of cost that enters a product (i.e., materials, labor, and overheads).

- Simplifies and speeds up the recording process, especially when actual cost data are not readily available.

- Once historical data is collected, businesses must consider industry benchmarks.

- Low morale for some workers The management by exception approach focuses on the unusual variances.

- This reflects the view that a standard cost represents the best judgment of management about what costs the business operations will involve when undertaken efficiently.

- Management by exception is another managerial approach in which management gives attention to matters that materially deviate from established standards.

Variance and Standard Cost

- Cost accounting is usually carried out by the management of the business for internal reasons.

- Standard costs also assist the management team when making decisions about long-term pricing.

- To ascertain production costs at the beginning of an accounting period, he considered the company’s production process, past trends, and anticipated market conditions in the future.

- Furthermore, classifying costs can also help the management recognize high cost areas and reduce the costs within those areas.

By aligning their cost expectations with these benchmarks, businesses can ensure that their standard costs are competitive and reflective of broader market conditions. This step is particularly important for companies operating in highly competitive industries, where cost efficiency can be a significant differentiator. Standard labor costs are calculated by considering the time required to complete a task and the wage rate of the employees involved. This process often includes time and motion studies to ensure that the labor standards are realistic and achievable. By setting these standards, businesses can monitor labor efficiency and identify areas for improvement.

How confident are you in your long term financial plan?

- This means that DenimWorks will never have work-in-process inventory at the end of an accounting period.

- Further investigation should revealwhether the exception or variance was caused by the inefficient useof materials or resulted from higher prices due to inflation orinefficient purchasing.

- Standard cost, or “pre-set costs,” gives the basis for budgeting and reduces unpredictability to some extent.

- A currently attainable standard is one that represents the best attainable performance.

- Cost-accounting systems, and the techniques that are used with them, can have a high start-up cost to develop and implement.

- Thus, in a standard cost system, acompany assumes that all units of a given product produced during aparticular time period have the same unit cost.

Cost accounting is the branch of accounting which, as the name suggests, deals with the recording, analyzing and reporting of the costs of a business. Cost accounting is usually carried out by the management of the business for internal reasons. These reasons may include helping in the decision-making process of a business, increasing the efficiency and effectiveness of different processes and for the preparation of budgets. Since cost accounting is used internally and not shared with external parties, such as shareholders, cost accounting does not require to be reported using specific standards or rules.

Understanding Issued Shares: Types, Processes, and Financial Impact

It can be achieved with reasonable effort (i.e., if the company operates with a “high” degree of efficiency and effectiveness). They are projections that are rarely revised or updated to reflect changes in products, prices, and methods. Ideal standards, also called perfection standards, are established on a maximum efficiency level with no unplanned work stoppages. A standard is essentially an expression of quantity, whereas a standard cost is its monetary expression (i.e., quantity multiplied by price). Codes and symbols are assigned to different accounts to make the collection and analysis of costs more quick and convenient. A cost center is a location, person, or item of equipment (or a group of these) for which costs may be ascertained and used for the purpose of cost control.

Ideal, Perfect or Theoretical standards

More reasonable and easierinventory measurements A standard cost system provideseasier inventory valuation than an actual cost system. Under anactual cost system, unit costs for batches of identical productsmay differ widely. For example, this variation can occur because ofa machine malfunction during the production of a given batch thatincreases the labor and overhead charged to that batch.